Janakpuri, Delhi

- GST NO. : 24AACCC7566J1ZG

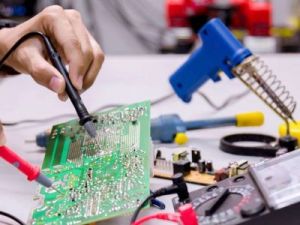

Through Hole Technology - Printed Circuit Board Assembly

Mixed Insertion

- Mixed insertion" is an assembly process in which different types of components are inserted into a printed circuit board (PCB). In mixed insertion, the PCB assembly may involve a combination of through-hole components and surface-mount components.

- Through-hole components have leads that are inserted into drilled holes on the PCB and soldered on the opposite side. Surface-mount components, on the other hand, are soldered directly onto the surface of the PCB without the need for holes.

WAVE SOLDERING

- Wave soldering is used to solder through-hole components onto printed circuit boards (PCBs). It is a highly efficient and reliable process that allows for the simultaneous soldering of multiple components.

LEAD CUTTING

- Wave soldering is used to solder through-hole components onto printed circuit boards (PCBs). It is a highly efficient and reliable process that allows for the simultaneous soldering of multiple components.

CLEANING

- Wave soldering is used to solder through-hole components onto printed circuit boards (PCBs). It is a highly efficient and reliable process that allows for the simultaneous soldering of multiple components.

TOUCHUP

- Wave soldering is used to solder through-hole components onto printed circuit boards (PCBs). It is a highly efficient and reliable process that allows for the simultaneous soldering of multiple components.

Looking for "Throuh-Hole Technology (THT) Assembly" ?

Piece

Explore More Services

Our Blogs