Janakpuri, Delhi

- GST NO. : 24AACCC7566J1ZG

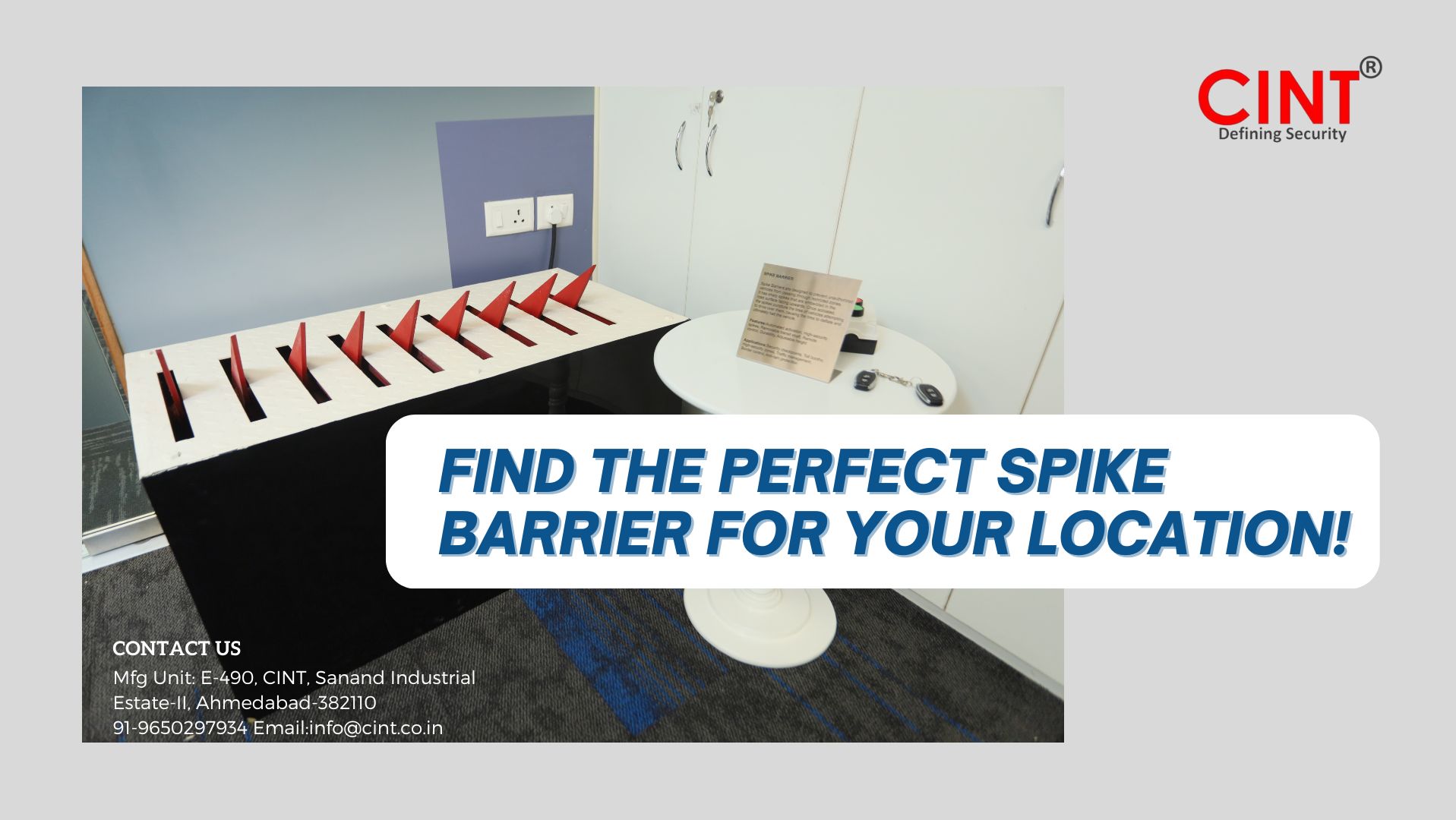

Understanding The Differences Among Manual, Electro-Mechanical And Electro-Hydraulic Spike Barriers

Posted by Admin on December, 03, 2024

Among the many security systems available for perimeter security, spike barriers have emerged as a critical security system. These are, often installed at entry and exit points, serve as an effective deterrent against unauthorized vehicular access. These also prevent vehicle ramming incidents in high security areas. Now let's explore the various mechanisms of spike barriers we manufacture and identify the best applications for each type.

A manual spike barrier is a type of security or traffic control system that uses sharp spikes to prevent unauthorized access or movement in a particular area. These manual spike barriers require human intervention to operate.

Features and Functionality

- Operation: These barriers are raised or lowered manually, often using levers.

- Power Source: They do not require electricity or any automated systems, making them a cost-effective option.

- Material: Typically made of robust steel, they are designed to withstand heavy vehicles.

- Suitability: Ideal for locations where vehicular traffic is minimal or security requirements are basic.

Advantages

- Low installation and maintenance costs.

- No dependency on electricity or hydraulic systems, making them suitable for remote areas.

- Durable and straightforward design.

Disadvantages

- Requires manual effort, which can lead to delays during high traffic or emergencies.

- Limited in terms of automation

- Less suited for high traffic areas.

Electro-Mechanical Spike Barrier

Electro-mechanical spike barriers utilize electric motors to drive mechanical systems, enabling the spikes to be raised or lowered with precision. This motorized mechanism ensures swift and efficient operation, making it a reliable choice for rapid deployment.

Features and Functionality

Operation: These barriers use electric motors to raise and lower spikes, controlled via switches or integrated security systems.

Power Source: Operates entirely on electrical energy, with options for power backup systems.

Material: Built with durable materials to ensure longevity and impact resistance.

Suitability: Ideal for facilities with moderate to high traffic, such as corporate offices, parking lots, and residential complexes.

Advantages

Ease of Installation, simpler setup compared to hydraulic systems.

Like electro-hydraulic systems, these can be integrated with modern access control technologies.

Affordable than electro-hydraulic barriers while still offering automation.

Disadvantages

Limited durability compared to hydraulic systems when dealing with extremely heavy vehicles or high-impact scenarios.

Requires maintenance of mechanical parts.

Electro-Hydraulic Spike Barriers

Electro-hydraulic spike barriers are powered by hydraulic systems, which are controlled by an electric motor. When activated, the motor pumps hydraulic fluid to raise or lower the spikes rapidly.

Features and Functionality

- Operation: These barriers are powered by hydraulic systems, which are controlled electronically.

- Power Source: Operates using an electrical power supply but can include battery backups for uninterrupted operation.

- Material: Constructed from heavy-duty materials to handle high-impact loads.

- Suitability: Commonly used in high-security areas such as airports, military facilities, and industrial zones.

Advantages

- These Can be operated remotely, allowing for faster and more efficient traffic control.

- Designed to handle large volumes of heavy vehicles.

- Can be integrated with access control systems

- Hydraulic mechanisms ensure quieter and smoother operation compared to mechanical systems.

Disadvantages

- Higher installation and maintenance costs due to the complexity of hydraulic systems.

- Dependency on electricity and hydraulic components, which may require regular servicing.

Choosing the right spike barrier is crucial for ensuring the security and efficiency of your facility. At CINT, we offer a range of spike barriers tailored to different needs, from manual solutions for cost-effective applications to advanced electro-mechanical and electro-hydraulic options for high-security environments. Contact us today at +91-9650297934 or email info@cint.co.in to find the perfect fit for your location!

Search

Category

Recent Posts

- The Art and Precision of Wire Harness Processing

- Maximizing the lifespan of Electronic components through the use of Dry Cabinets

- Revolutionizing Road Safety: CINT's Automatic Spike Barriers in Ahmedabad

- Understanding the differences among Manual, Electro-Mechanical and Electro-Hydraulic Spike Barriers

- Empowering Agriculture with CINT's Agrihector: A New Era of Precision Farming

Leave a Comment